The Parts You Need to Build a Bulletproof Ford 9" Rear End

If you don't know, the Ford 9" axle is amazing. Not just because it's good by itself, but because it has a ton of aftermarket support.

You can literally build a complete Ford 9" from brand new parts on the Internet!

Not so easy with a lot of other axles!

In this article, we'll take a look at parts you can slap on your 9" to make it stronger and perform better.

A Better Ford 9" Third Member

For most applications, it makes a lot of sense to upgrade the third member to a nodular one.

One of the things that make Ford 9" axles so desirable is the drop-out differential. The drop-out third member makes it easy to swap thirds, setup a ring and pinion on your workbench, or install a locker into your 9".

Otherwise, you're often stuck under your rig, banging your head and wondering if you should just pull your whole rear end.

(Side note: The Ford 9" also does not require a case spreader.)

There are a number of ways you can upgrade the third as a complete unit.

The Nodular Ford 9" Third

Many nodular third members for the 9" use a larger aftermarket-only 3.250" carrier bearing.

The favorite stock diff for 9 inch junkies is the nodular case diff. It has a big "N" on it above the pinion.

However, you're pretty unlikely to find one hanging out at the local U-Pull-It as the vehicles that had them are old and most normal people aren't dumb enough to drop off their 429 CJ in a junkyard.

In the interest of preserving old stuff, it might even be better to sell an "N" case to someone who's doing a restoration - if you break it, it's broken for good.

Luckily, there are plenty of brand spanking new nodular iron cases out there and they aren't that expensive (relatively speaking).

Honestly, an nodular third member case is a no-brainer if you want a simple strength upgrade.

Should you get an aluminum third member?

There are lightweight aluminum third members for the 9", but they aren't for everyone.

If you're just running trails on the weekends, you most likely don't need an aluminum third.

If you're racing and need the weight savings, you might. This is more of a case of "you'll know when you need it".

- Some 9 inch aluminum third members aren't designed for the heat of long wheeling trips. They are suitable for short sprints at the track, but that isn't generally what we fourwheelers do.

- Aluminum diff cases deflect more than iron cases. This means that your ring and pinion will wear faster and maybe even that you'll crunch diff components in a high horsepower/high traction situation.

- An aluminum differential won't last long if you're grinding it on rocks all day long. Cast or nodular iron is much better for this.

On a related note, the TruHi9 (more on that later) specifically uses a nodular iron case. This is notable because the gearset runs on the coast side which causes even more deflection than a standard 9" low pinion setup.

Get Bigger Carrier Bearings

There is a small range of carrier bearings available for the 9".

Some are stock, but some are aftemarket only!

The largest option, a 3.250" bearing OD, will allow you to run larger 35 and 40 spline axle shafts. The 3.250" was never stock, but it will allow you to have a little more flexibility in aftermarket parts, especially if you think you might need more strength upgrades in the future. (There is a larger option, the 3.812", but it's for more specialized applications.)

The smaller options work for stock size axle shafts, 28 and 31 spline. It's possible to have a small bearing diff bored to fit larger bearings, but it probably makes more sense just to buy a large carrier bearing case unless you have a machinist buddy.

| Carrier Bearing Bore | Bearing OD | Bearing ID | Bearing/Race Part Numbers | Fits Axle Splines | Where found |

|---|---|---|---|---|---|

| 2.891" | 2.891" | 1.625" | LM501349/LM501310 | 28 | Found in '66-'77 Ford Bronco |

| 2.891" | 2.891" | 1.780" | LM102949/LM102910 | 28/31 | Stock/Probably most common |

| 3.062" | 3.062" | 1.780" | LM603049/LM603011 | 28/31 | Stock |

| 3.250" | 3.250" | 2.000" | LM104911/LM104949 | 31/35 | Aftermarket only |

| 3.812" | 3.812" | 2.250" | 35/40 | Aftermarket only |

Most aftermarket nodular iron and aluminum differentials for the Ford 9" will have either 3.062" or 3.250" carrier bearing bores.

If you're planning to buy a new carrier, it just makes a lot of sense to us to pick up the 3.250" bore differential and run at least 35 spline axles.

If you're trying to build a 9" with scrounged parts, check out our table and you can probably find a combo that will work for you.

For instance, you find that you've bought a locker that comes with carrier bearings, but they're the wrong size for your diff. You can often just fix this by using the chart and swapping in the right carrier bearings.

Knowing the carrier bearing size for your third member is important. Specifically:

- It's often referred to when you buy a locker or spool (i.e. "Fits a 2.891" case").

- It's referred to when you buy a new diff (i.e. "Currie Nodular 3.250" Third Member")

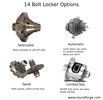

Ford 9" Locker Options

There are tons of locker options for the Ford 9 inch. Before you buy, there are a couple of important things you should know.

The Ford 9" has no carrier break. Other axles have carrier breaks where one subset of gear ratios fits on one carrier, and another subset of gear ratios fits on another carrier.

In other words, some axles come with two different carriers from the factory and these carriers usually use specific gears with a certain thickness.

Because of the design of the 9", you don't need to worry about this. All standard 9" gears made for the Ford 9" fit on the same carriers, limited slips, and lockers. This takes away a major point of confusion for a lot of builders.

If you're fitting a locker, spool, or limited slip in your 9 inch, remember:

Lockers are held in your differential housing by the carrier bearings, which are held in with the carrier bearing caps. This means that you need to make sure that your locker has the same carrier bearing OD as the third member.

You can read more about carrier bearing sizes above.

You also need to know the spline count of your axleshafts as this needs to match the spline count of the locker.

You'll typically see lockers with spline counts of 28, 31, 35, and 40. Most of us will want to avoid the weaker 28 spline shafts and use 31 or 35 spline shafts. If you need serious strength, pick the 40 spline. Just make sure you get the locker to match.

Selectables for the 9"

The best locker for most wheelers running a 9" rear end is a selectable.

Why? You can turn them on and off at will. Regular diff on the street, locked off road. Doesn't get much better. Of course, they are pricey.

Be forewarned that there are no electric selectable lockers for the 9" - the case is too small to fit the actuating mechanisms.

Two selectable lockers you can look at are:

The Ford 9" ARB Air Locker

Everyone knows the ARB. They are strong and trouble-free. They take a little more setup than an electric, since you need to run a compressor to use it, but it gets the job done reliably.

This locker comes in these configurations:

- 31 splines (fits your stock carrier bearings)

- 35 splines (requires larger 3.250" carrier bearings)

- 35 splines with stronger competition components (requires larger 3.250" carrier bearings)

- 40 splines with strongest competition components (strongest available!)

The Ford 9" Yukon Zip Locker

The Yukon Zip locker also actuates with air. Sometimes, you can find these on sale for a good bit less than an ARB.

This locker comes in these configurations:

- 31 splines (fits your stock carrier bearings)

- 35 splines (requires larger 3.250" carrier bearings)

Automatic Lockers for Your 9"

Automatic lockers operate themselves. These are a little less street-friendly than selectable lockers, but they are also usually a little bit cheaper.

Some rear ends have exceptionally strong carriers. For instance, in a 14 bolt rear end, a Detroit installs straight into the stock carrier.

However, in a Ford 9" the case is not as strong and needs to be replaced. Unfortunately, this makes extremely strong locker options like the Detroit a bit more expensive. It's definitely worth it to compare Detroit prices to selectables when you finally buy - the difference might be less than you think.

The Ford 9" Detroit Locker

This is a strong, very common locker option.

Note that this locker DOES come in a 28 spline version.

But frankly, if you're going to drop the coin on this thing, you should also be upgrading to at least 31 spline axle shafts. The 28 and 31 spline lockers cost about the same and 31 spline shafts will give you a significant strength upgrade.

This locker comes in these configurations:

- 28 splines (fits your stock carrier bearings)

- 31 splines (fits your stock carrier bearings)

- 35 splines (requires larger 3.250" carrier bearings)

The 9" Lock Right

The Power Trax Lock Right is a much simpler locker that installs straight into your Ford 9 inch's carrier. Of all the lockers here, it's the only one that doesn't replace the carrier.

This means:

- It's weaker than a locker that DOES replace the carrier.

- It can be installed into any stock Ford 9" carrier - any of the stock carrier bearings will work, and either of the stock 28 or 31 spline axleshafts will work.

- It doesn't required you to set up your ring and pinion.

That last point is really notable if you're on a budget. Since you aren't replacing the carrier, you never need to unbolt your ring gear. Therefore, you don't need to setup the gears.

Besides the unit itself being cheaper, not needing to set up the rear end gears really makes this locker very economical.

It comes in one configuration:

- 28 or 31 spline (fits your stock carrier bearings)

Upgrade the Pinion Support

Always go with the bigger bearing, stronger Daytona pinion support if you're buying a new one!

The 9 inch's pinion support (also referred to as the pinion bearing retainer) tends to be pretty weak for wheeling:

It's not uncommon for them to crack, which usually ends with you blowing apart the entire third member.

Ford even recognized some of the weaknesses of the support and made a stronger retainer:

The nodular "N" diffs came with a stronger support known as the "Daytona". Compared to a standard 9" diff pinion support, they have:

- Same size outer bearings

- Larger inner bearing

- Stronger inner webbing

- A spacer plus shims instead of a crush sleeve

If Ford did it to strengthen their nodular "N" thirds, that's a good sign that you should get a stronger pinion support as well!

Luckily, there are a TON of pinion supports out there. You can pick up a factory Ford Daytona support or upgrade to something like the Yukon Gear Daytona-style pinion support.

Daytona pinion supports require a shorter pinion yoke, like this one.

Make sure you're using a short pinion yoke that's compatible with the Daytona pinion, like this one from Yukon.

You may find some manufacturers offering "stronger" pinion supports that DON'T use the Daytona bearing.

Avoid the small bearing:

We highly recommend that you get a pinion support that uses the larger Daytona bearing to reduce the deflection your pinion can experience.

Get Bigger Axle Shafts for Your 9"

The Ford 9" came stock with either 28 or 31 spline axles. In the aftermarket, you can now buy axles with 28, 31, 33, 35, or 40 splines.

How do you decide on splines?

First, we recommend that you stay away from 28 spline axles. They're just going to be a weak link in your axle.

Also avoid 33 spline axle shafts for your Ford 9". These tend to not have as many locker, spool, and posi options.

That leaves us with 31, 35, and 40 spline axles!

Clearly, if you need the most strength, you're going to be looking at 40 spline. With the right amount of horsepower, you can easily snap your 35 splines. There are some drawbacks, though. The axleshaft diameter is large enough that bearing thickness will start to become an issue - this can lead to premature wearing if you take your 4x4 on the road frequently.

Additionally, there still aren't as many lockers and limited slips available for 40 spline axles as there are for the 31/35 spline axles. ARB did release a very expensive 40 spline air locker, but you're probably going to need to invest pretty heavily in the third member and shafts to make it work.

Our preference is for 31 or 35 spline shafts unless you need the crazy strength of a 40 spline setup. There are tons of lockers/spools/limited slips available for these spline counts, and they'll easily fit into a standard aftermarket nodular third member.

Keep in mind:

There are many possible axleshaft configurations depending on the width of your rear, spline count, lug nut pattern, brake type, etc. If you're building a 9" yourself, expect to need some custom axle shafts.

Put in Some 9" Full Floating Axle Shafts

Stock Ford 9" rear ends only ever came in a semi-floating configuration. Lots of semi-floaters use a c-clip to retain the semi-float axleshaft, but not the 9":

It uses a bolt-on flange at each end of the housing.

If you break an axleshaft, you can conceivably drive home on the broken axle, since it'll be retained by the flange retainer. Of course, you should fish out any broken parts and pieces from inside the axle housing because they'll just grind up inside your bearings and gears.

How a Full Floating 9" Is Different

If you want a stronger, better option, take a look at a full float kit for your 9".

Full float axleshafts mean that the axleshaft just transmits power to your wheels - the shafts don't also have to carry vehicle load like with semi-float axles.

You can also drive on full float hubs without axles installed indefinitely, meaning that as long as you pull broken parts out of the 9 inch's axle housing, you can drive or get towed out to a road.

A full float kit requires:

- Axleshafts

- Housing ends + oil retention

- Full float hubs

- Some kind of brake setup

There are plenty of DIYers doing full float conversions using weld-on housing ends, but it might be easier to buy a complete full floating Ford 9" housing. Full float conversions usually require machining, jigs to keep components aligned, and lots of careful measuring. It's a lot of work.

If you poke around, you'll see 9" full floating conversions with:

- Dana 60 ends

- Ford TTB ends

- Corporate 14 bolt ends

- and probably a bunch more

Truss the Top and Back of Your Nine

This is a simple top truss for the 9". You can extend the bracing to the sides with optional side arms.

While you can wheel without a truss on your 9", it seems dumb.

Why?

A strong 9" with a nodular diff and 31 spline axles is fairly comparable in strength to a stock Dana 60 rear end. But the 9" is better in a couple respects:

- It's much lighter than a Dana 60.

- It has more ground clearance than a Dana 60.

For the Ford 9" rear end to be smaller and lighter than a Dana 60, the weight has to come from somewhere.

One of those "somewheres" is the axle housing!

A top truss like this adds strength, but also a lot of flat spots and surface area for welding on link mounts.

Stockers are just stamped steel welded together - pretty thin stuff.

If you're going to be beating on your 9", you can beef it up significantly by adding a top and back truss.

Which should you do if you can only do one?

We'd go for the top truss. This will add stiffness to your housing while also providing lots of flat surfaces for welding on link brackets.

RuffStuff Specialties sells a weld-on top truss with optional extension arms. Artec also sells a much more "involved" truss for the 9".

A back truss will also keep your axle from bending. Take a look at the one from RuffStuff.

Swap in a Thicker, Large Tube Axle Housing

The Roller Kit means that you have a full axle once you add shafts and a third!

As we said above, the stock Ford 9" axle housing is thin stamped steel that are welded together.

The stockers have been known to leak at seams and also bend if you wheel hard.

You've got a ton of options for buying a new axle housing. Here are a few of them:

Width

Many 9" housing makers will send you either a "standardised" housing width, or will custom cut and weld one at your request.

For instance, the Trail Gear Rock Assault 9s come in 60", 65", and 68" WMS to WMS.

For parts availability, we do like the idea of picking a standardised width. It makes replacing axleshafts a lot easier if you can throw in an off-the-shelf, full floating, 35 spline, 34" long axle.

Tube diameter and thickness

With a 72" width, this housing can be cut down to fit any width you want. Configurable with a centered pinion or equal length axle shafts.

Bigger tubes equals more strength. Generally, aftermarket Ford 9" housings are available with these tube sizes:

- 3"

- 3.25"

- 3.5"

- 4"

- 4.5"

Now, not all manufacturers make all their housings with all of these tube sizes. For most wheelers, we'd go with a 3" or a 3.5" axle tube (the 3.5" is stronger). 3.5" is very common, plenty strong, and there are lots of complementary parts that are made to fit its diameter.

For thickness, you'll see either 1/4" or 3/8". Either one is strong, but the 3/8" is clearly stronger. If you're trimming weight, you might want to figure out if you want a thick tube without a truss or a thin tube with a truss.

Space for a larger ring gear

Since the ring gear on a 9" is a weak spot in high HP, high torque situations, there are beefier gearsets available for it. (Ah yes, just when is a Ford 9" no longer a 9"?)

Most fabricated 9" housings will accommodate the larger gear set, but probably not the "stock appearance" ones. If you want to go with 10" gears, pick the right housing!

You might be wondering how much clearance a 10" ring gear costs you. After all, a larger ring gear requires a larger pumpkin to clear it.

But most 10" ring gears for the 9" aren't actually 10" in diameter:

They're closer to 9.5".

So really a fabricated 9" axle housing only needs to be about 1/2" larger, top to bottom, in order to fit 10" gears. This translates into a pumpkin that's only 1/4" lower than a standard 9" housing. Not too shabby.

Strap Some Armor on Your 9"

If you believe that there's never too much protection on your rig, think about adding some armor.

There are two areas that you might want to consider beefing up:

Under the pinion

A beefy pinion guard (this one uses 1/2" steel on the face and 3/8" on the surround) will protect the Ford 9 inch's low pinion.

The Ford 9 inch's pinion is particularly vulnerable, due to the fact that it hangs down so low.

It's likely that your pinion is going to see a lot of bashing if you're running rocks!

Protect it with a pinion guard, also from RuffStuff.

There are a few things we really like about the guard:

- It's super strong. The mounting plate is 1/2" thick and the "surround" is 3/8" steel.

- Its face fully covers the pinion support and uses the same bolt holes, which means that the pinion support and front and of the third member are reinforced by that extra 1/2" of material.

Under the pumpkin

You can weld a skidplate under the pumpkin on your 9". For a little bit of extra weight, you can significantly increase the strength of the bottom of the lowest-hanging part of your axle.

RuffStuff Specialties makes one that's designed to fit their 3.5" 9" axle housing.

Crank the Stopping Power Rear Disc Brakes

This rear disc kit bolts to the 9 inch's axle flange and has a built in parking brake inside the rotor.

Everybody wants rear discs on their wheeling rig's rear end!

Rear discs are really a huge improvement to how your rig stops. Performance-wise, you'll get better stopping power and less brake fade.

Discs work also better than drums when they're wet.

But two places they really shine on a 9" axle:

- Weight! You can drop 60-70 lbs off your 9" axle with a disc brake conversion.

- Maintenance: They have fewer moving parts than drums, less stuff to rust, and are easier to remove when you need to pull an axleshaft.

For a 9", there are tons of kits out there.

Keep in mind that there are three different axle flanges that came on the 9". Particularly if a disc brake conversion kit includes a parking brake, you'll need to match up the backing plate to the flange.

For example, this 9" disc brake conversion kit from Yukon Gear uses drums that operate/fit inside the brake rotor. The drum parking brake components attach to the backing plate which bolts to the 9" end flange.

On the other end, you can get a kit like RuffStuff Specialties' 9" disc conversion.

This weld-on disc brake kit will go on any Ford 9" with 3.5" OD axle tubes. You don't need to worry about the axle flange pattern.

This kit uses weld-on caliper brackets. Since they're weld-on, they need to match your 9" axle's tube diameter. But in this case you don't need to worry about the flange pattern on the end of the axle.

You may wonder about using a parking brake with this setup:

RuffStuff offers a kit both without a parking brake, and with calipers that have the parking function built-in. These are the famous (infamous?) Caddy El Dorado calipers. We've used the Caddy calipers before and they were a pain. However, RuffStuff is shipping new calipers, not clapped out junkyard trash or "remanufactured" garbage.

Slam in Some Bigger Gears

Did you know you can go to a phyiscally larger ring and pinion set in your Ford 9" rear end?

If you're the type of guy that strips off gear teeth and snaps pinions, you might think about going to what are known as 10" gears in the Ford 9" differential.

The larger gearsets give you two big benefits:

- A larger tooth profile: You get stronger teeth with more contact.

- A 1.5" 35 spline pinion: Obviously stronger than the 28 spline stocker.

- Typically made from 9310. 8620 is used to make most gearset and lots of lockers.

You might be surprised to learn that 10" gears in a 9" are stronger than even a 14 bolt's for 3 more reasons:

- Their increased size

- The hypoid design

- Ring gear to carrier bearing distance (shorter in the 9")

The typical "10 inch" gears aren't actually THAT much bigger than a traditional 9" ring and pinion. Many of them actually run around 9.5" in outside diameter, which means that the axle housing only needs to be another 1/4" bigger all around.

In other words, an aftermarket Ford 9" rear end housing only loses about 1/4" of ground clearance in order to fit 10" gears.

There are a few things you should know, though:

- 10" gears are expensive and really oriented to high strength applications. (Seriously, they're 4-5x the price of a standard R&P.)

- You'll need an aftermarket 3rd member that will fit the larger gear set. Most aftermarket diffs are big enough. However, the larger R&Ps won't fit into a stock 9" differential.

- 10" gears tend to be noisier than stock. If you're installing them, they are a performance mod. Emphasis on the performance. They also tend to have a shorter life span.

Make Your 9" a High Pinion

9" rear ends have a low pinion. While the low pinion design contributes to the axle's strength, it's also very vulnerable to rock damage and can kill your driveline angles. You have three options here:

- Add a pinion guard and continue dragging it over rocks with steep driveshafts.

- Aim the pinion at the transfer case output to lift it out of the way.

- Go to a Ford 9" high pinion setup.

We're going to take a quick look at #3.

There are two kinds of high pinion 9" diff out in the wild: those that use a 9" gearset and those that use the later Ford 8.8" gearset. Today, you can only get the true 9" gearset.

In a front axle, a high pinion is stronger than a low pinion diff due to the way the teeth mesh between the ring and pinion.

However, in a 9" rear end, power is transmitted through the coast side of the gear, which basically makes the pinion want to push away from the ring gear.

It's extremely unlikely that we're ever going to see high pinion 9" gears that are cut for a rear application in the near future.

Fortunately, this deflection can be controlled for by using a thrust block behind the ring gear that keeps it from being pushed out by the pinion. Since the 9" has a third pinion bearing on its snout and also can be equipped with a thrust block, it's one of the strongest high pinion diffs that can accommodate high horsepower applications in a high pinion configuration.

TruHi9's High Pinion

This is the only Ford 9" High Pinion third member currently on the market. It uses some unique design features to make it light and extremely strong.

TruHi9 is the strongest option you've got for a high pinion 9". It uses Ford 9" style gears that are custom cut, uses a third pinion bearing (the third bearing is stock in the 9", but wasn't used in Currie's Hi9 below), and uses a thrustblock ring gear support.

There are pros and cons to this setup. First, it's likely to be the most expensive option - that's simply what it costs to be the strongest. It'll fit just about any aftermarket Ford 9" housing, although if you're spending the coin on this setup, it would be silly not to use a superstrong fabricated 9" housing.

This is a highly modified setup that cannot use stock cases or gears.

It's the only new option out there for a high pinion 9" right now.

Currie's High Pinion

These are not available any more, but you can still buy parts and gears for them.

It's also likely that you can still find these on the used market. Currie's high pinion setup was weaker, but less expensive, than the TruHi9.

The biggest difference between the Currie and TruHi9 setups is that the Currie third member used the later Ford 8.8" gearset (commonly found in Explorers).

They did not provision for the third pinion bearing or the thrust block that makes the TruHi9 so strong.

As a result, Currie generally suggested sticking to less than 400 horsepower and using 35" or smaller tires. Generally, the high pinion third was strong enough in the front for a lot of applications, but a little weaker in the rear.

Last updated: October 28, 2019