Repairing a Radiator by Rodding or Recoring

Many new cars have radiators with aluminum cores and plastic tanks

that are glued together. This is a cheap and efficient construction

method, but when the radiator goes bad, it generally can't be repaired -

it's time to buy a new one.

Heater cores can also be repaired in similar ways since they are really just small radiators.

Recoring a Radiator

Radiator cores are somewhat standardized. It's possible for a radiator shop to buy large pieces of radiator core and then resize them to fit a given radiator. Recoring a radiator generally looks like this:

- You punch a hole in your radiator or it's clogged up. You take your radiator to a competent rad shop.

- The radiator artisan sizes out your core to find a piece of core of the proper width and height.

- A too-wide piece of core can be resized - tubes and fins are desoldered from one side to make the core the proper width. Now you have a new core.

- The top and bottom tanks are desoldered from your old radiator.

- Everything is thoroughly cleaned in muriatic acid.

- The tanks are soldered to the new radiator core and leak-tested.

This process is referred to as recoring. Why are the tanks reused?

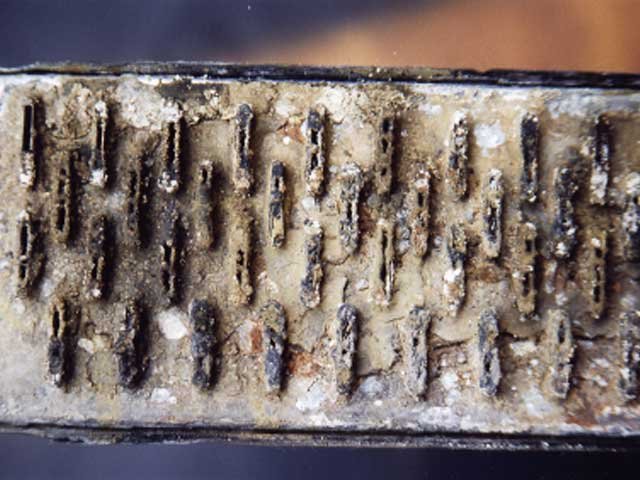

You typically have more problems with the core leaking or being damaged.

The tubes and fins are somewhat exposed and made of pretty thin metal so they're easy to puncture or break.

Rodding a Radiator

Often, an old radiator is clogged, but not actually leaking. If the core has no punctures or damage, it can be reused. Rodding a radiator looks like this:

- You take your clogged but undamaged radiator to a competent rad shop.

- The top and bottom tanks are desoldered from your old radiator.

- A thin rod is run through each core to dislodge any debris.

- Everything is thoroughly cleaned in muriatic acid.

- The tanks are soldered to the new radiator core and leak-tested.

If You Decide to Attempt a Radiator Repair on Your Own

We recommend against doing the radiator repairs above, mostly because the chances that you'll damage your radiator or hurt yourself are extremely high. But if you do:

Do lots of research, especially when something involves heat and fire or chemicals.

Use extremely low heat to desolder the tanks. Propane is okay, but MAPP gas and oxy-acetylene will probably burn a hole in your tanks pretty quickly. While the core material can be replaced fairly easily, the tanks are usually specific to your vehicle.

Muriatic acid dissolves aluminum. Don't let muriatic acid contact any aluminum parts.

Muriatic acid is extremely dangerous. Use goggles, face shield, and total body protection. Use in an extremely well-ventilated area because there will be burning, toxic fumes.

Last updated: June 3, 2019